Choosing between Fe 500 and Fe 550 TMT bars depends entirely on the type of structure you’re building. For most residential and light commercial projects, Fe 500 TMT bars are the ideal choice due to their excellent balance of strength and flexibility. However, for high-rise buildings, bridges, and heavy-load-bearing structures, Fe 550 TMT bars offer higher tensile strength, making them more suitable for demanding environments.

What Are TMT Bars?

TMT (Thermo-Mechanically Treated) bars are high-strength reinforcement bars with a tough outer core and a soft inner core. They are essential in construction for providing durability, strength, and safety, especially in earthquake-prone or coastal areas. TMT bars come in various grades such as Fe 500, Fe 500D, Fe 550, and Fe 550D, where “Fe” denotes iron, and the number indicates the minimum yield strength in N/mm².

What Is Fe 500 TMT Bar?

Fe 500 TMT bar has a yield strength of 500 N/mm², which makes it ideal for medium to heavy-duty construction projects. Its balanced properties of tensile strength and ductility make it suitable for a wide range of structural applications.

Fe 500 TMT bar has a yield strength of 500 N/mm², which makes it ideal for medium to heavy-duty construction projects. Its balanced properties of tensile strength and ductility make it suitable for a wide range of structural applications.

| Key Properties: | Ideal Applications: |

|---|---|

| High tensile strength | Residential buildings |

| Good elongation and ductility | Commercial complexes |

| Resistant to earthquakes and vibrations | Bridges and flyovers |

| Easy to bend without cracking | Earthquake-prone zones |

What Is Fe 550 TMT Bar?

Fe 550 TMT bar has a higher yield strength of 550 N/mm², classifying it among high-strength TMT bars. This makes it stronger than Fe 500, though it offers slightly less ductility. This grade is ideal for projects where high load-bearing capacity and structural strength are more critical than flexibility.

| Key Properties: | Ideal Applications: |

|---|---|

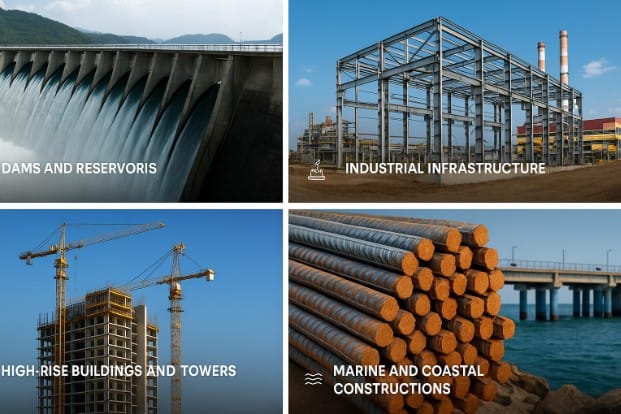

| Higher tensile and yield strength | Dams and reservoirs |

| Lower elongation compared to Fe 500 | Industrial infrastructure |

| Highly resistant to corrosion and stress | High-rise buildings and towers |

| Designed for heavy-duty and large-scale structures | Marine and coastal constructions |

Fe 500 vs Fe 550 TMT Bars: Key Differences

| Feature | Fe 500 | Fe 550 |

|---|---|---|

| Yield Strength | 500 N/mm² | 550 N/mm² |

| Tensile Strength | ~545 N/mm² | ~585 N/mm² |

| Elongation | ~16% | ~14% |

| Ductility | Higher | Slightly lower |

| Bending Properties | Excellent | Good |

| Applications | Residential, commercial, seismic zones | High-rise, industrial, coastal areas |

Which One Should You Choose?

The choice between Fe 500 and Fe 550 depends on the following factors:

1. Type of Project:

- Fe 500 is suitable for residential buildings and standard commercial structures due to its ductility and ease of use.

- Fe 550 is preferred for massive infrastructure like metro projects, highways, or skyscrapers for its higher strength.

2. Location:

- For earthquake-prone areas, Fe 500 is ideal because of its superior elongation and energy absorption.

- For coastal or saline environments, Fe 550 CRS (Corrosion Resistant Steel) is recommended to prevent rust and corrosion.

3. Budget and Cost Efficiency:

- Fe 500 is generally more cost-effective for low to mid-scale construction.

- Fe 550 may cost slightly more, but it offers long-term value in demanding projects due to its higher strength.

4. Structural Load Requirements:

- Fe 550 is the better choice for structures expected to carry heavy loads.

- Fe 500 is adequate for general load-bearing structures.

Benefits of Using Rama TMT Bars

Whether you choose Fe 500 or Fe 550, opting for a reputed brand like Rama TMT ensures consistent quality, advanced German Thermex technology, and BIS certification. Rama TMT bars manufacturer uses state-of-the-art processes to deliver:

- Superior bonding with concrete

- High corrosion resistance

- Excellent weldability

- Uniform quality across batches

Engineer’s Recommendation

Most civil engineers follow a blended approach:

- Use Fe 500 for slabs, beams, and load-sharing components that require flexibility.

- Use Fe 550 for columns, foundations, and external parts exposed to high stress or environmental hazards.

This strategy ensures both cost-efficiency and structural stability.

There’s no one-size-fits-all answer. Both Fe 500 and Fe 550 TMT bars have their unique advantages, and the right choice depends on the nature, scale, and location of your project. For high-rise or heavy infrastructure projects, Fe 550 offers superior strength. For residential and earthquake-resistant constructions, Fe 500 offers better ductility and ease of use.